Work Order & Inventory Management

You need a single platform to track and manage all inventory aspects of your business.

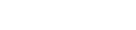

How Does it work?

Too much material in stock means you are carrying big numbers in inventory. Too little and your customer service wanes. You need a single platform to track and manage all aspects of your business.

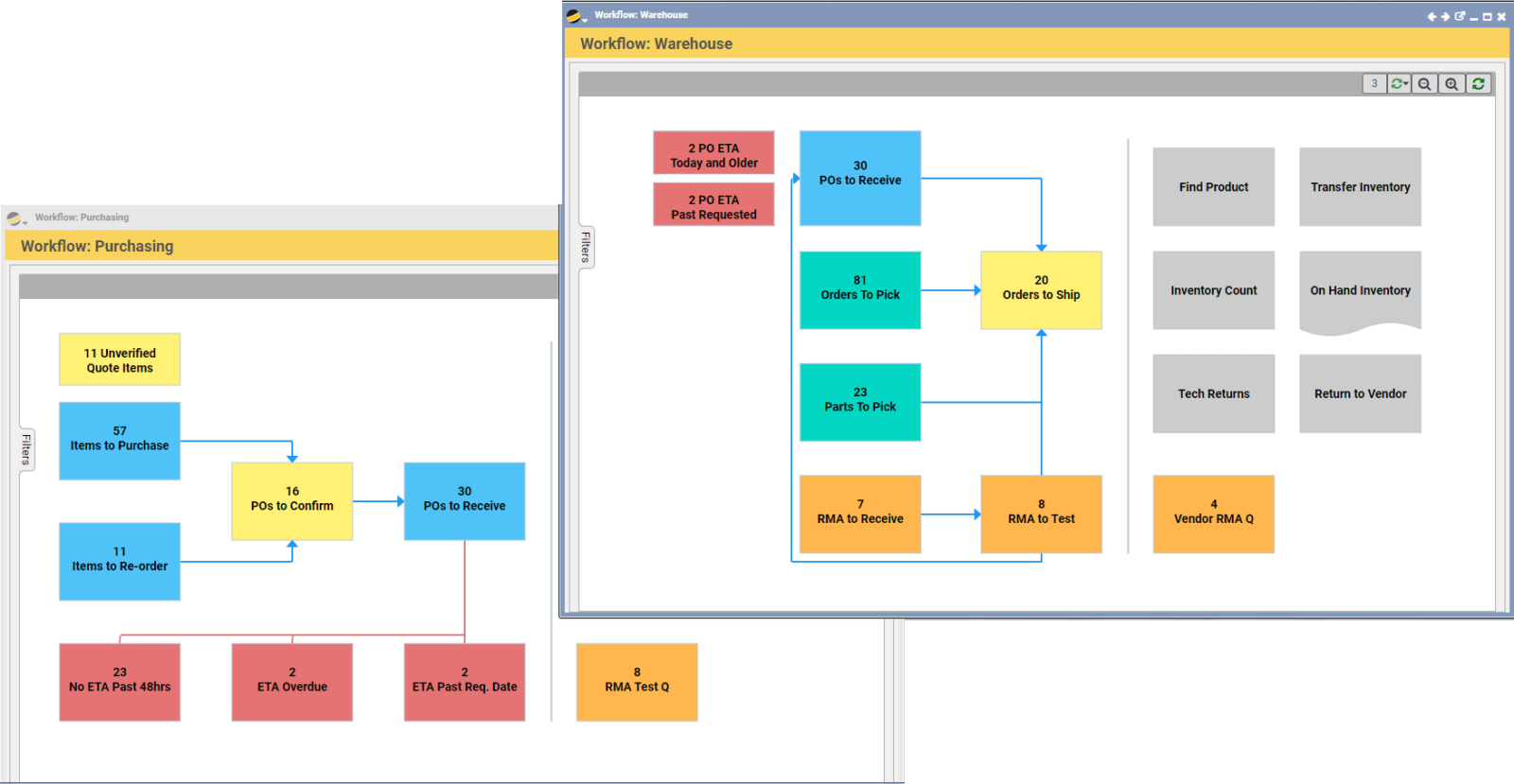

Word of mouth and paper-based tracking are the downfall to tracking, managing and controlling inventory. When inventory walks out the door or worse yet, wasn’t there to begin with, your customer and your reputation suffers. We have an inventory system that works – Q360™ keeps track of the history of inventory so you know when demand spikes and other key inventory metrics. Q360™ allows you to keep absolute minimal stock levels while still providing a high level of service and automatically tracks drop-ship processing.

Automating your workorder processing ensures you are billing for parts correctly and accounting for parts used for warranty and service contract work as well as new job material usage. Seamlessly move inventory from a technician’s truck stock to a customer`s inventory from the field or within the dispatch call center.

Taking the guesswork out of billing a service call workorder ensures you are not leaking dollars from labor and materials consumed in the field.

- Keep minimal stock levels with reorder amounts and historical consumption factors

- Track inventory within warehouses, within fulfillment and in service vehicles

- Close the loop on customer and vendor RMA’s

- Allocate inventory on quotes and orders across warehouses

- Manage drop-shipments on projects and work in progress